Welcome to Scopione’s Carbon Fiber Glossary — your definitive reference for understanding the materials, processes, and jargon behind high-performance carbon components. Whether you’re new to composites or a seasoned builder, this page empowers you to:

- Decode terms like prepreg, void content, and weave patterns

- Compare methods such as wet vs. dry (pre-preg) carbon

- Understand resins & finishes to evaluate performance and durability

- Make confident decisions when selecting premium parts

At Scopione, we believe that informed customers make smarter choices — and that clarity builds trust. Dive in, explore the definitions, and reach out anytime for deeper insight or tailored advice.

Table of Contents

- Introduction to ScopioneCarbon

- What is Carbon Fiber?

- How is Carbon Fiber Made?

- What is ‘Grade A’ Carbon?

- What is the Difference Between Wet and Dry (Pre-preg) Carbon Fiber?

- What is Dry Carbon Fiber?

- What is Wet Carbon Fiber?

- What is Pre-preg Carbon Fiber?

- What is a Weave?

- What is the Difference Between 1×1 and 2×2 Weaves?

- What are Epoxy, Vinylester, and Polyester Resins?

- What are Surface Treatments and Finishes?

- What are Advantages of Carbon Fiber in Automotive Applications?

- Other Terms Explained

- Frequently Asked Questions (FAQs)

- Care and Maintenance of Carbon Fiber Parts

- Summary

ScopioneCarbon: Precision in Every Detail

Every ScopioneCarbon part is engineered with Toray pre-preg dry carbon fiber sheets and advanced epoxy resins, creating components that deliver unmatched strength, lightweight performance, and durability. Each piece is finished with a UV-resistant clear coat, protecting against fading while maintaining a deep, glossy shine for years to come.

Our mission is simple: provide performance-driven carbon fiber parts that enthusiasts and professionals can trust. From automotive to motorcycle applications, ScopioneCarbon products are crafted to exceed expectations in fitment, quality, and long-term reliability.

Why Carbon Fiber Matters

Carbon fiber is the ultimate material in modern performance engineering. Lightweight yet stronger than steel, it offers a superior strength-to-weight ratio, making it indispensable in industries where every gram counts.

In automotive and motorcycle customization, carbon fiber delivers:

- Weight reduction for faster acceleration and improved handling

- Aerodynamic efficiency for greater stability at speed

- Motorsport-grade durability with impact resistance beyond aluminum

- A high-tech aesthetic that enhances a vehicle’s visual appeal

These advantages explain why carbon fiber has become the go-to choice for both enthusiasts and manufacturers worldwide.

The Rise of Carbon Fiber Technology

Once reserved for aerospace and Formula 1, carbon fiber has now become more accessible thanks to advances in production and design. Modern processes allow ScopioneCarbon to create aftermarket upgrades that are not only lighter and stronger, but also precisely engineered for exact OEM fitment.

The result? Premium parts that improve both performance and appearance, trusted by those who demand nothing less than excellence.

Knowledge + Innovation = The Scopione Advantage

We know carbon fiber can be complex. That’s why we created this Carbon Fiber Glossary — to explain essential terms, from pre-preg to weave patterns, in plain language. Whether you’re exploring your first upgrade or fine-tuning your build, we want you to make informed decisions with total confidence.

At Scopione, our focus is not only on delivering top-tier products, but also on building a community that values innovation, education, and performance.

Upgrade with ScopioneCarbon

Whether your goal is to shave weight, boost performance, or elevate style, ScopioneCarbon is your trusted source for premium carbon fiber automotive and motorcycle parts.

Explore our collection today — experience the craftsmanship, durability, and innovation that set Scopione apart.

What Is Carbon Fiber and Why It Matters in Automotive Performance

Once reserved for aerospace due to its high cost, carbon fiber has become one of today’s most sought-after performance materials. From motorsports and supercars to wind energy and sporting goods, it is valued for being both extremely strong and exceptionally lightweight. This unique balance makes carbon fiber an ideal replacement for traditional materials like steel, aluminum, or plastic in high-end applications — especially where speed, precision, and durability are critical.

At its core, carbon fiber is made from ultra-thin strands of carbon, spun and woven into fabrics, then bonded together with high-strength resins. When cured under heat and pressure, the result is a composite material with an extraordinary strength-to-weight ratio, perfect for building lightweight yet reliable components.

How Carbon Fiber Is Made: From Fibers to High-Strength Composites

Carbon fibers are derived from base materials such as polyacrylonitrile (PAN) fibers or pitch, both of which are processed at extremely high temperatures. The result is thousands of carbon filaments bundled into threads, then woven into a cloth-like fabric.

When this fabric is combined with epoxy resins and cured, it transforms into a rigid, durable structure. Compared to steel, carbon fiber offers:

- Up to 10x the strength by weight

- Around 75% less weight for comparable parts

- Superior resistance to deformation and fatigue

- Better efficiency, handling, and performance in vehicles

This is why ScopioneCarbon parts don’t just look premium — they are engineered to perform at the highest level. Explore our precision-fit upgrades for the Lamborghini Aventador, Audi R8, and Ferrari 488 to see how carbon fiber transforms both performance and style.

Understanding “Grade A” Carbon Fiber

The term “Grade A” carbon fiber is often used in the market, but it is not an official industry standard. Instead, it’s a marketing label intended to signal high quality. At Scopione, we take quality far beyond labels.

We source our carbon fiber from Toray Industries, Inc., the global leader in advanced composites and the supplier trusted by top automakers worldwide. By using Toray pre-preg dry carbon sheets and proven epoxy formulas, we ensure every part we produce delivers:

- Motorsport-level durability

- Precise OEM fitment

- UV-resistant finishes for long-lasting shine

- The performance and reliability enthusiasts expect from a premium aftermarket upgrade

When you choose Scopione, you’re not just buying “Grade A” carbon — you’re investing in true aerospace-inspired engineering for the street and track.

Learn in-depth about Why Is Carbon Fiber So Expensive? Is It Worth the Cost? here:

- Why Does Carbon Fiber Cost So Much?

- Is Carbon Fiber Worth the Cost?

- When Is Carbon Fiber NOT Worth It?

Wet vs Dry Carbon Fiber: Key Differences Explained

Understanding the difference between dry and wet carbon fiber is crucial when selecting the right materials for your project. These two processes result in distinct differences in strength, weight, and cost. Below, we break down the pros and cons of each to help you make an informed decision.

What is Dry Carbon Fiber and Why It’s the Top Choice?

Dry carbon fiber uses pre-impregnated resin (pre-preg), which is sealed into a vacuum mold for curing. This process creates a stronger, lighter, and more durable product, perfect for performance applications like high-end automotive parts.

Advantages:

- Up to 60% lighter than wet carbon fiber

- Stronger and more durable

- Fewer imperfections and a matte finish

Disadvantages:

- Expensive (3–4 times more costly than wet carbon fiber)

- Requires a UV-protective clear coat for longevity

Understanding Wet Carbon Fiber: Cost-Effective but Less Durable

Wet carbon fiber is made by manually applying resin over dry carbon fabric. While the process is more affordable, it can result in heavier parts with air pockets, making it less durable than dry carbon.

Advantages:

- Affordable for more budget-conscious builds

- Glossy finish for aesthetic appeal

Disadvantages:

- Heavier and weaker than dry carbon

- Prone to imperfections like air pockets and uneven weaves

What is Pre-preg Carbon Fiber?

Pre-preg carbon fiber is the premium choice for high-performance parts. Made with pre-impregnated resin, it undergoes a high-pressure curing process to eliminate imperfections and create lightweight, strong components.

Key Differences at a Glance

| Feature | Dry (Pre-preg) | Wet |

|---|---|---|

| Weight | Lighter | Heavier |

| Strength | Stronger | Weaker |

| Cost | Expensive | Affordable |

| Appearance | Matte | Glossy |

| Consistency | Minimal imperfections | Air pockets |

If performance, weight reduction, and strength are critical, dry carbon fiber is your best choice. But if budget is your primary concern and you’re looking for an attractive glossy finish, wet carbon fiber may be the right option.

What Is a Carbon Fiber Weave?

The term “weave” refers to the pattern formed when carbon fiber strands, called tows, are woven into a fabric. Each weave style affects not only the look of the finished part but also its strength, flexibility, and best applications. Knowing the differences helps you choose the right material for both performance and appearance.

Plain Weave: Stable and Balanced

Plain weave carbon fiber has a checkerboard-style pattern created by an over-under weaving technique. Its short interlace distance makes it highly stable, helping the fabric maintain its shape and fiber orientation.

Advantages of Plain Weave:

- Stable structure that resists distortion

- Ideal for flat sheets, tubes, and simple 2D curves

- Balanced, symmetrical appearance

Limitations of Plain Weave:

- Less flexible for complex curves

- Sharp crimps at interlace points may create stress concentrations in high-stress applications

Plain weave is best when strength and stability matter more than aesthetics, often used for structural components and flat panels.

Twill Weave: Flexible and Stylish

Twill weave is more pliable and versatile, allowing it to conform to complex contours while maintaining good strength. Its distinctive diagonal “twill line” pattern makes it one of the most recognizable and visually appealing carbon weaves.

- 2×2 Twill: Each tow passes over two and under two — the most common weave in automotive applications

- 4×4 Twill: Each tow passes over four and under four, producing a looser weave

Advantages of Twill Weave:

- More flexible than plain weave, ideal for complex shapes

- Fewer crimps, reducing stress points

- Distinctive diagonal pattern popular in automotive styling

- Balanced mix of strength and aesthetics

Because of its premium look, 2×2 twill weave is widely used in visible parts such as hoods, diffusers, spoilers, and interior trims. It has become the signature weave in high-end applications across the automotive and aerospace industries.

How to Choose the Right Carbon Fiber Weave

Choosing the right weave depends on your goals:

- Choose Plain Weave if:

- You need stability for flat or simple shapes

- Structural integrity is more important than flexibility

- Choose Twill Weave if:

- You want versatility for curved, complex parts

- You value both strength and premium aesthetics

At Scopione, most high-visibility carbon fiber upgrades — like Lamborghini Huracan diffusers, McLaren 570S intake vents, and Ferrari 458 engine covers — are crafted in the iconic 2×2 twill weave for the perfect balance of performance and style.

1×1 vs 2×2 Carbon Fiber Weave: What’s the Difference?

When choosing carbon fiber parts, you’ll often see 1×1 and 2×2 weave patterns. The difference lies in the weave style:

- 1×1 weave → Checkerboard pattern, uniform and stable

- 2×2 weave → Diagonal pattern, more flexible and premium-looking

Both are lightweight, durable, and popular in automotive and aerospace use, but each has strengths depending on your project.

1×1 Weave: Stable and Checkerboard Pattern

The 1×1 weave uses a tight, symmetrical checkerboard layout. It offers excellent stability and a clean, OEM-style look.

Advantages:

- ✅ Strong and stable, resists distortion

- ✅ Affordable due to simpler weaving process

- ✅ Clean checkerboard appearance

Limitations:

- ❌ Less flexible, harder to mold over complex curves

- ❌ Limited adaptability for intricate contours

Applications:

Ideal for flat or gently curved parts such as roof panels (e.g., BMW M3 roofs) or structural-grade components where rigidity matters most.

2×2 Weave: Flexible and Diagonal Pattern

The 2×2 weave is the most widely used in automotive aftermarket upgrades. Its diagonal “twill line” pattern gives parts a stylish, high-end finish while allowing greater flexibility during production.

Advantages:

- ✅ More pliable, fits complex curves and angles

- ✅ Fewer crimps = fewer weak points

- ✅ Distinctive diagonal look popular in supercars & aftermarket parts

Limitations:

- ❌ Slightly less stable than 1×1

- ❌ Higher cost due to more complex manufacturing

Applications:

The preferred weave for visible performance upgrades, such as:

- Lamborghini Gallardo dash trims & engine covers

- Nissan GTR R35 air vents & wheel covers

- Maserati GranTurismo splitters & mirror covers

Side-by-Side Comparison

| Feature | 1×1 Weave | 2×2 Weave |

|---|---|---|

| Pattern | Checkerboard | Diagonal (twill line) |

| Flexibility | Low – best for simple shapes | High – conforms to complex curves |

| Stability | Very stable, resists distortion | Slightly less stable |

| Cost | More affordable | Higher due to complexity |

| Appearance | Clean, OEM style | Premium, stylish, most recognizable |

Other Weave Patterns

While 1×1 and 2×2 are the most common, other weaves exist:

- Satin (4-, 5-, 8-harness): Increasing flexibility and smoother finishes

- Unidirectional: Strength in one direction for structural components

- Triaxial: Multi-directional reinforcement for durability

- 4×4 weave: Balanced compromise between strength and flexibility

Which Carbon Fiber Weave Should You Choose?

- Choose 1×1 for flat panels, roofs, or structural parts where strength and uniformity are key.

- Choose 2×2 for visible, complex, or curved parts where both style and performance matter.

At Scopione, we specialize in 2×2 twill weave for most aftermarket upgrades because it delivers the perfect balance of strength, flexibility, and iconic style.

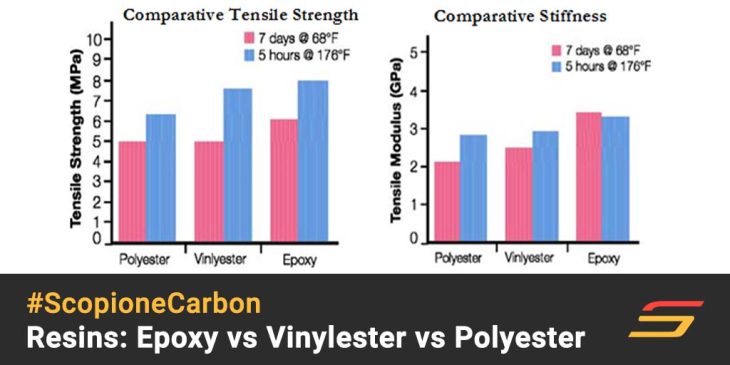

Epoxy vs Vinylester vs Polyester Resins in Carbon Fiber Parts

When evaluating carbon fiber parts, it’s not just the weave that matters — the resin system plays an equally important role. The resin binds the fibers together, determines durability, and affects cost. The three most common resin types in automotive carbon fiber applications are epoxy, vinylester, and polyester.

Understanding their strengths and limitations ensures you choose parts that deliver the right balance of performance, appearance, and value.

Epoxy Resin: Strongest and Most Durable

Epoxy resin is the gold standard for carbon fiber parts. It provides the highest strength, stiffness, and resistance to fatigue.

Advantages:

- ✅ Strongest & most durable (highest tensile strength)

- ✅ Best adhesion to carbon fiber, Kevlar, and fiberglass

- ✅ Superior resistance to water, chemicals, and osmosis

- ✅ Available in specialized formulations for heat or performance needs

Limitations:

- ❌ Higher cost compared to vinylester or polyester

- ❌ UV sensitivity (can yellow without UV-protected finishes)

- ❌ May form amine blush (a waxy film during curing that must be cleaned)

Scopione Standard:

At Scopione, we use epoxy resins with built-in UV protection, ensuring your parts maintain both strength and appearance for years to come.

Vinylester Resin: Balanced but Less Strong

Vinylester resin is moderately strong — about one-third as strong as epoxy — but offers certain cosmetic and practical benefits.

Advantages:

- ✅ More affordable than epoxy

- ✅ Better adhesion to fiberglass than polyester

- ✅ Often used for surface finishes to enhance appearance

Limitations:

- ❌ Weaker bond with carbon fiber & Kevlar

- ❌ Lower strength and durability compared to epoxy

Use Case:

Best for cosmetic parts or coatings where appearance matters more than structural performance.

Polyester Resin: Lowest Cost, Lowest Strength

Polyester resin is the least expensive but also the least effective when it comes to carbon fiber. It bonds poorly to carbon fiber and Kevlar, though it is widely used with fiberglass.

Advantages:

- ✅ Very low cost

- ✅ Works acceptably with fiberglass

Limitations:

- ❌ Weak bonding to carbon fiber and Kevlar

- ❌ Poor strength and durability for automotive applications

- ❌ Not recommended for performance-grade parts

Use Case:

Suitable only for fiberglass-based components where cost savings matter more than performance.

Side-by-Side Comparison

| Resin Type | Strength & Durability | Bonding Quality | Cost | Best Use Case |

|---|---|---|---|---|

| Epoxy | ⭐⭐⭐⭐⭐ Highest | Excellent with CF/Kevlar/Fiberglass | $$$ | High-performance carbon fiber parts |

| Vinylester | ⭐⭐ Moderate | Fair with CF, strong with fiberglass | $$ | Cosmetic finishes, fiberglass blends |

| Polyester | ⭐ Lowest | Poor with CF/Kevlar, fair with fiberglass | $ | Fiberglass-only parts |

Which Resin Should You Choose?

- Choose Epoxy if you want maximum strength, durability, and premium performance.

- Choose Vinylester if you’re on a budget and value appearance over strength.

- Avoid Polyester for critical carbon fiber components — it’s only viable for low-cost fiberglass builds.

ScopioneCarbon Advantage: All our premium carbon fiber upgrades use epoxy resin systems from world-class suppliers, ensuring superior bonding strength, UV resistance, and long-lasting performance compared to cheaper alternatives.

Carbon Fiber Surface Treatments & Finishes Explained

The surface treatment or finish of a carbon fiber part affects not only its appearance, but also its durability, UV protection, and handling performance. Choosing the right finish ensures you get the balance of style, strength, and maintenance that fits your needs.

Appearance Finishes

Glossy Finish

- Appearance: High-gloss, mirror-like surface that highlights the carbon fiber weave.

- Advantages: Maximum depth and visual appeal; popular in luxury and show applications.

- Best For: Hoods, spoilers, and aero accents where a striking look matters most.

- Considerations: Shows fingerprints and scratches more easily; requires care.

Matte Finish

- Appearance: Subdued, non-reflective surface with weave still visible.

- Advantages: Conceals scratches and fingerprints; sleek, modern look.

- Best For: Trim pieces, interior accents, or frequently handled parts.

Satin Finish

- Appearance: Balanced, soft sheen between gloss and matte.

- Advantages: Refined look with reduced reflectivity; versatile and durable.

- Best For: Versatile applications where both style and practicality matter.

Painted Finish

- Appearance: Opaque color applied over the carbon fiber, hiding the weave.

- Advantages: Unlimited customization; extra environmental protection.

- Best For: Custom builds, color-matched accents, and motorsport styling.

Performance Finishes

Clearcoat Finish

- Appearance: Transparent gloss or matte layer.

- Advantages: Adds UV protection, durability, and depth.

- Best For: Outdoor-exposed parts — such as Lamborghini Aventador diffusers and Audi R8 hoods.

Textured / Peel-Ply Finish

- Appearance: Rough, sandpaper-like surface.

- Advantages: Excellent for bonding adhesives or layering.

- Best For: Structural or hidden components.

Sanded Finish

- Appearance: Smooth, matte surface achieved by sanding outer resin.

- Advantages: Removes imperfections; ready for paint or additional coatings.

- Best For: Prep stages before painting or secondary finishing.

Specialty Finishes

Forged Carbon Finish

- Appearance: Unique marbled pattern created by randomly arranged carbon fiber fragments.

- Advantages: Eye-catching, exclusive, associated with high-end supercars.

- Best For: Luxury upgrades, like Bentley Continental GT trims or special-edition components.

Choosing the Right Finish

- Glossy: Best for visual impact on show cars and aero parts.

- Matte/Satin: Durable and practical for everyday use or frequently handled parts.

- Forged Carbon: Unique, luxury look to stand out from traditional weaves.

- Performance Finishes (Clearcoat, Textured, Sanded): For protection, prep, or hidden structural components.

- Painted: For full customization and color-matched builds.

ScopioneCarbon Advantage: All our premium carbon fiber parts feature UV-protected clearcoats to ensure long-lasting durability, while select components are available in glossy, satin, matte, or forged finishes — giving you both performance and style.

Advantages of Carbon Fiber in Cars & Performance Upgrades

Carbon fiber isn’t just lightweight — it’s a revolution in automotive engineering. By combining strength, flexibility, and style, it delivers benefits far beyond traditional materials like steel or aluminum. Here’s why ScopioneCarbon parts set the standard for performance enthusiasts worldwide:

1. Weight Reduction & Efficiency

- Up to 75% lighter than steel and 50% lighter than aluminum

- Improves fuel efficiency and extends EV driving range

- Lower weight = faster lap times, better acceleration, and more agile cornering

2. Strength & Durability

- Exceptional strength-to-weight ratio (up to 10x stronger than steel by weight)

- Corrosion-proof — carbon fiber won’t rust or oxidize

- Long-lasting durability with UV-protected clearcoats (standard in Scopione parts)

3. Performance & Handling

- Reduced mass improves braking responsiveness

- Enhances maneuverability and steering precision

- Trusted in motorsports for delivering consistent high-speed stability

4. Design Flexibility & Aesthetics

- Can be molded into complex aerodynamic shapes

- Iconic 1×1 and 2×2 weave patterns showcase racing heritage

- Available in gloss, matte, satin, or forged finishes for a premium look

5. Thermal Stability & Safety

- Maintains structural integrity under extreme heat (engine bays, brakes, exhaust surrounds)

- Can absorb and dissipate impact energy, improving crash safety

- Preferred material in supercar monocoques and aerospace engineering

6. Sustainability & Environmental Benefits

- Lighter vehicles = reduced emissions over their lifetime

- Recycling technologies now enable carbon fiber re-use

- Aligns with modern demand for eco-friendly, high-performance engineering

Why Choose ScopioneCarbon?

At Scopione, every part is engineered with Toray pre-preg carbon fiber sheets and epoxy resin systems with UV protection, ensuring long-lasting strength, finish, and fitment.

That’s why owners of the many exotic car models trust ScopioneCarbon upgrades to deliver both performance and aesthetics.

Upgrade today and experience the unmatched strength, style, and innovation of ScopioneCarbon parts.

Other Terms Explained

- What is Tow, Roving, or Strand?

- What is a Composite Material?

- What is a Matrix in Composite Materials?

- What is PAN?

- What is Filament?

- What is a Ply?

- What is Laminate?

- What is Fiber Orientation?

- How Precursors for Polyacrylonitrile (PAN) Is Created?

- What is Axial?

- What is the Autoclave Process?

- What is Carbonization?

- What is Modulus?

- What is Electrical Conductivity?

- What is Oxidation or Stabilization?

- What is Precursor?

- What is Tensile Strength?

- What is Shear Strength?

- What is Void Content?

- What is Wet Layup?

- What is Prepreg?

- What is Cure Cycle?

- What is Resin?

- What is Thermoset vs. Thermoplastic?

- What is Layup Schedule?

- What is Cross-Ply?

- What is Fatigue Resistance?

- What is Delamination?

- What is Isotropic vs. Anisotropic?

Carbon Fiber Basics

Tow (Strand / Roving)

- Definition: A tow is a bundle of thousands of carbon fiber filaments packaged on a spool (also called “strand” or “roving”). For example, a 3K tow contains 3,000 fibers.

- Why It Matters: Tow size determines the weave pattern, flexibility, and appearance of carbon fiber parts.

- Example: Smaller tows (3K, 6K) give a fine, cosmetic look for interior trims, while larger tows (12K–24K) are stronger and often used in large body panels like hoods or diffusers.

Filament

- Definition: A single, ultra-thin strand of carbon fiber — about 5–10 microns in diameter (much thinner than a human hair).

- Why It Matters: Bundled filaments form tows, which create fabrics for composites. The strength of each filament contributes to the overall performance of the material.

- Example: Every ScopioneCarbon panel is made from millions of these filaments, aligned to maximize tensile strength and durability.

Ply

- Definition: A ply is a single layer of carbon fiber fabric.

- Why It Matters: Engineers stack multiple plies in different orientations to achieve strength in multiple directions.

- Example: A Scopione diffuser might have several plies — some oriented at 0° for lengthwise strength, others at 90° or 45° for shear resistance.

Laminate

- Definition: A laminate is the final structure created by stacking multiple plies together.

- Why It Matters: The performance of a laminate depends on fiber orientation, resin type, and curing process.

- Example: Premium laminates made with pre-preg epoxy carbon fiber (like those used in Scopione parts) are stronger and lighter than wet-layup alternatives.

Matrix

- Definition: The matrix is the resin system (epoxy, vinylester, or polyester) that binds carbon fibers together.

- Why It Matters: While weaker than the fibers themselves, the matrix distributes loads, protects against moisture, and ensures durability.

- Example: Scopione exclusively uses epoxy resin systems with UV protection to maximize part longevity and appearance.

Carbon Fiber Manufacturing Processes

Ply

- Definition: A ply is a single layer of carbon fiber fabric.

- Why It Matters: Engineers stack multiple plies in different orientations to achieve strength in multiple directions.

- Example: A Scopione diffuser might have several plies — some oriented at 0° for lengthwise strength, others at 90° or 45° for shear resistance.

Laminate

- Definition: A laminate is the final structure created by stacking multiple plies together.

- Why It Matters: The performance of a laminate depends on fiber orientation, resin type, and curing process.

- Example: Premium laminates made with pre-preg epoxy carbon fiber (like those used in Scopione parts) are stronger and lighter than wet-layup alternatives.

What is Fiber Orientation?

Fiber orientation describes the direction in which the fibers are aligned within a composite ply. Common orientations include 0°, 45°, and 90° angles. Proper fiber orientation is critical for ensuring the composite can withstand forces in specific directions.

How Precursors For Carbon Fiber Polyacrylonitrile (PAN) Is Created?

What is Axial?

Axial refers to a characteristic or property aligned with the direction of the fiber orientation. In the context of composite materials, “axial” typically describes forces or stresses applied parallel to the fiber direction, where the fibers exhibit maximum strength and stiffness.

What is the Autoclave Process?

The autoclave process involves placing an object inside a sealed vessel where it is subjected to controlled levels of heat and fluid pressure. This process is commonly used in the production of high-performance composite materials, such as carbon fiber components, to ensure thorough bonding and curing of the materials.

What is Carbonization?

Carbonization is the thermal process in which stabilized PAN fibers or pitch fibers are heated to temperatures between 1200°C and 1500°C. During this process, non-carbon elements are driven off, leaving behind fibers composed almost entirely of carbon. This transformation maximizes the strength of the fibers and enhances their modulus (stiffness).

What is Modulus?

Modulus is a measure of a material’s stiffness, defined as the ratio of stress to strain within the elastic range of the material. A higher modulus indicates a stiffer material, which resists deformation under applied loads. Carbon fiber is prized for its high modulus, which makes it ideal for applications that require minimal deflection or bending.

What is Electrical Conductivity?

Electrical conductivity measures a material’s ability to conduct electrical current. Carbon fiber, for example, is an excellent conductor of electricity, while fiberglass is not. In boat construction, electrical conductivity is an important consideration due to the risk of galvanic corrosion, which can occur when dissimilar conductive materials are exposed to an electrolyte, such as seawater.

What is Oxidation or Stabilization?

Oxidation or stabilization is a thermal process where the PAN precursor undergoes chemical changes that transform it into a cross-linked, thermoset material. This stabilized material can maintain its structural shape during the subsequent carbonization process, making it a crucial step in the production of carbon fibers.

What is Precursor?

A precursor is the raw material used to create carbon fibers. For PAN-based carbon fibers, the precursor is polyacrylonitrile. For pitch-based carbon fibers, the precursor materials are derived from petroleum-based or coal tar-based compounds. The choice of precursor significantly influences the properties of the resulting carbon fibers, such as strength, stiffness, and cost.

What is Tensile Strength?

Tensile strength is the maximum amount of tensile (pulling) stress that a material can withstand before breaking. Carbon fiber is known for its exceptionally high tensile strength, making it ideal for applications where tension forces are prevalent.

What is Shear Strength?

Shear strength refers to a material’s ability to resist sliding forces along a plane. In composite materials, shear strength is an important property, particularly at the interface between fibers and the matrix.

What is Void Content?

Void content refers to the amount of air pockets or voids present within a composite material. High void content weakens the composite and reduces its mechanical properties. Proper processing methods, such as using an autoclave, minimize void content and improve overall strength.

What is Wet Layup?

Wet layup is a method of composite fabrication where fiber materials (such as carbon fiber sheets) are manually laid out and impregnated with liquid resin before being cured. It is a more labor-intensive and lower-cost process compared to automated methods like prepreg layup.

What is Prepreg?

Prepreg refers to fiber reinforcements (such as carbon fiber fabric) that have been pre-impregnated with a specific amount of resin and partially cured. Prepregs offer precise control over the resin-to-fiber ratio and are commonly used in high-performance applications such as aerospace and motorsports.

What is Cure Cycle?

A cure cycle is the specific sequence of temperatures, pressures, and times used to cure a composite material. Proper curing is essential to achieve optimal bonding and mechanical properties of the composite.

What is Resin?

Resin is the polymer material that forms the matrix in composite materials. Common types of resins used in composites include epoxy, polyester, and vinyl ester. The resin binds the fibers together and provides shape, durability, and resistance to environmental conditions.

What is Thermoset vs. Thermoplastic?

- Thermoset resins, such as epoxy, undergo an irreversible chemical reaction during curing, creating a rigid structure.

- Thermoplastics can be heated, reshaped, and cooled multiple times, making them more versatile but often less stiff compared to thermosets.

What is Layup Schedule?

A layup schedule is a detailed plan that specifies the number, type, and orientation of the plies in a laminate. It ensures that the composite is manufactured to meet specific performance criteria.

What is Cross-Ply?

Cross-ply refers to a laminate design where layers are alternately oriented at 0° and 90° angles. This configuration provides balanced strength and stiffness in perpendicular directions.

What is Fatigue Resistance?

Fatigue resistance is a material’s ability to withstand repeated cycles of loading and unloading without failure. Carbon fiber composites generally have excellent fatigue resistance, making them ideal for applications subjected to cyclic stresses, such as wind turbines and aircraft structures.

What is Delamination?

Delamination occurs when layers within a laminate separate or peel apart, usually due to defects, impact damage, or improper bonding. Delamination can significantly weaken the structure and reduce its mechanical performance.

What is Isotropic vs. Anisotropic?

- Isotropic materials have uniform mechanical properties in all directions.

- Anisotropic materials, such as carbon fiber composites, have different properties depending on the direction of the applied load. This makes fiber orientation crucial in composite design.

Frequently Asked Questions (FAQs)

Why is carbon fiber used in automotive parts?

- Answer: Carbon fiber is a lightweight, high-strength material composed of thin strands of carbon atoms. These strands are woven into fabrics and combined with resins to create composite materials. In automotive applications, carbon fiber is favored for its superior strength-to-weight ratio, enhancing vehicle performance, fuel efficiency, and aesthetics.

How does carbon fiber compare to traditional materials like steel or aluminum?

- Answer: Carbon fiber offers comparable or superior strength to steel and aluminum but at a fraction of the weight. This weight reduction leads to improved acceleration, handling, and fuel efficiency in vehicles. Additionally, carbon fiber is corrosion-resistant and can be molded into complex shapes, providing both functional and aesthetic benefits.

What are the differences between dry (pre-preg) and wet carbon fiber?

- Answer: Dry carbon fiber, or pre-preg, involves fibers pre-impregnated with resin, allowing for precise resin control and resulting in higher strength and lighter weight. Wet carbon fiber is manually coated with resin during the molding process, which can lead to variations in resin content and potentially lower strength-to-weight ratios.

Can carbon fiber parts be repaired if damaged?

- Answer: Yes, carbon fiber parts can often be repaired, depending on the extent and location of the damage. Minor surface scratches can be polished out, while more significant structural damage may require professional assessment and repair to ensure safety and integrity.

How should I care for and maintain carbon fiber components on my vehicle?

- Answer: To maintain carbon fiber parts, regularly clean them with a soft cloth and mild soap. Avoid abrasive cleaners or tools that could scratch the surface. Applying a UV-protectant can help prevent sun damage, and promptly addressing any chips or cracks will maintain both appearance and structural integrity.

Are carbon fiber parts compatible with all vehicle models?

- Answer: Compatibility depends on the specific part and vehicle model. It’s essential to verify that the carbon fiber component is designed for your vehicle’s make and model to ensure proper fitment and functionality. Consulting with the manufacturer or a knowledgeable retailer can provide guidance on compatibility.

Do carbon fiber parts affect vehicle safety?

- Answer: High-quality carbon fiber parts are designed to meet or exceed safety standards. However, it’s crucial to ensure that any aftermarket parts are properly installed and compatible with your vehicle. Improper installation or the use of substandard components can negatively impact safety.

Why do some carbon fiber parts have different weave patterns, and do they affect performance?

- Answer: Different weave patterns, such as plain weave or twill weave, primarily affect the aesthetic appearance of carbon fiber parts. While the weave can influence the material’s flexibility and drapability during manufacturing, it generally does not significantly impact the performance of the finished component.

Are there color options available for carbon fiber parts?

- Answer: Traditional carbon fiber has a distinctive black or dark gray appearance due to its natural composition. However, colored carbon fiber can be produced by incorporating pigments into the resin or using colored fibers, allowing for customization to match personal preferences or vehicle aesthetics.

Is carbon fiber resistant to corrosion?

- Answer: Yes, carbon fiber is naturally resistant to corrosion, unlike metals that can rust over time. This property makes it particularly advantageous for automotive parts exposed to various environmental conditions, ensuring longevity and reduced maintenance.

Is carbon fiber environmentally friendly?

- Answer: The production of carbon fiber involves energy-intensive processes, raising environmental concerns. However, the use of carbon fiber in vehicles can lead to weight reduction, improving fuel efficiency and reducing emissions over the vehicle’s lifespan. Additionally, advancements in recycling technologies are being developed to address end-of-life disposal of carbon fiber components.

Care and Maintenance of Carbon Fiber Parts

Proper care and maintenance of carbon fiber automotive parts are essential to preserve their appearance, structural integrity, and longevity. Here’s an expanded guide to help you maintain your carbon fiber components effectively:

1. Regular Cleaning

- Gentle Washing: Use a mild automotive-specific cleaner or pH-neutral soap with a soft microfiber cloth to clean carbon fiber surfaces. Avoid harsh chemicals, as they can damage the clear coat protecting the carbon fiber.

- Avoid Abrasive Materials: Steer clear of abrasive brushes or rough sponges that could scratch the surface. Instead, opt for soft-bristled brushes or microfiber towels to gently remove dirt and grime.

2. Protection from UV Exposure

- UV-Resistant Coatings: Apply a high-quality wax or ceramic coating that offers UV protection to shield the carbon fiber from sun damage. Regular application helps maintain the glossy finish and prevents oxidation.

- Parking Considerations: Whenever possible, park your vehicle in shaded areas or use a car cover to minimize direct sunlight exposure, reducing the risk of UV-induced fading or discoloration.

3. Inspection and Damage Prevention

- Regular Inspections: Periodically examine carbon fiber parts for signs of damage, such as cracks, chips, or delamination. Early detection allows for timely repairs, preventing further deterioration.

- Avoid Chemical Exposure: Keep carbon fiber components away from harsh chemicals like gasoline, brake fluid, or solvents, as they can corrode or damage the surface. In case of accidental exposure, clean the area immediately with a mild soap and water solution.

4. Polishing and Restoration

- Addressing Oxidation: If the carbon fiber surface becomes oxidized or yellowed, use a fine-grade polish with a soft polishing pad to restore clarity and shine. For heavily oxidized surfaces, professional restoration may be necessary.

- Protective Coatings: After polishing, apply a protective sealant or ceramic coating to enhance the surface’s resistance to environmental factors and maintain its luster.

5. Maintenance Best Practices

- Avoid High-Pressure Washing: Refrain from using high-pressure water jets directly on carbon fiber parts, as they can cause delamination or force water into areas that may lead to damage. Instead, use a gentle stream of water during cleaning.

- Temperature Considerations: Protect carbon fiber components from extreme temperatures, as excessive heat can affect the resin matrix, leading to potential structural issues. Avoid parking near heat sources or exposing the vehicle to extreme cold without adequate protection.

By following these guidelines, you can ensure that your carbon fiber automotive parts remain in excellent condition, enhancing both the aesthetic appeal and performance of your vehicle.

Congratulations! You now have a comprehensive understanding of the fundamental terminology associated with the carbon fiber parts production process. At Scopione, we are dedicated to delivering the highest quality carbon fiber components and providing exceptional customer service. Our team of experts is always available to answer any questions you may have—whether they pertain to the terminology explained on this page or any other aspect of carbon fiber parts.

We believe that education and open communication are key to ensuring our customers receive the best possible products and service. By equipping our customers with essential knowledge, we aim to create a seamless and rewarding experience that fosters confidence and trust.

In addition to offering premium carbon fiber parts, we provide a wide range of customization options. We understand that each customer has unique preferences and requirements, which is why we are committed to offering tailored solutions that meet your specific needs. Whether you are looking for unique finishes, custom dimensions, or specialized performance attributes, our customization process is designed to bring your vision to life.

Furthermore, at Scopione, we continuously invest in research and development to stay at the forefront of the carbon fiber industry. Our team is dedicated to exploring and testing new materials, designs, and manufacturing techniques to ensure our products remain cutting-edge and of superior quality. This commitment to innovation allows us to offer durable, lightweight, and high-performance components that exceed industry standards.

To summarize, Scopione is dedicated to providing industry-leading carbon fiber parts backed by exceptional customer support, versatile customization options, and a strong commitment to research and innovation. We encourage you to reach out with any questions or requests—our team is ready to assist you at every step of the way. Thank you for choosing Scopione; we look forward to serving you with unparalleled products and service.