Welcome to Scopione’s Carbon Fiber Glossary — your definitive reference for understanding the materials, processes, and jargon behind high-performance carbon components. Whether you’re new to composites or a seasoned builder, this page empowers you to:

- Decode terms like prepreg, void content, and weave patterns

- Compare methods such as wet vs. dry (pre-preg) carbon

- Understand resins & finishes to evaluate performance and durability

- Make confident decisions when selecting premium parts

At Scopione, we believe that informed customers make smarter choices — and that clarity builds trust. Dive in, explore the definitions, and reach out anytime for deeper insight or tailored advice.

ScopioneCarbon: Precision in Every Detail

Every ScopioneCarbon part is engineered with Toray pre-preg dry carbon fiber sheets and advanced epoxy resins, creating components that deliver unmatched strength, lightweight performance, and durability. Each piece is finished with a UV-resistant clear coat, protecting against fading while maintaining a deep, glossy shine for years to come.

Our mission is simple: provide performance-driven carbon fiber parts that enthusiasts and professionals can trust. From automotive to motorcycle applications, ScopioneCarbon products are crafted to exceed expectations in fitment, quality, and long-term reliability.

Why Carbon Fiber Matters

Carbon fiber is the ultimate material in modern performance engineering. Lightweight yet stronger than steel, it offers a superior strength-to-weight ratio, making it indispensable in industries where every gram counts.

In automotive and motorcycle customization, carbon fiber delivers:

- Weight reduction for faster acceleration and improved handling

- Aerodynamic efficiency for greater stability at speed

- Motorsport-grade durability with impact resistance beyond aluminum

- A high-tech aesthetic that enhances a vehicle’s visual appeal

These advantages explain why carbon fiber has become the go-to choice for both enthusiasts and manufacturers worldwide.

The Rise of Carbon Fiber Technology

Once reserved for aerospace and Formula 1, carbon fiber has now become more accessible thanks to advances in production and design. Modern processes allow ScopioneCarbon to create aftermarket upgrades that are not only lighter and stronger, but also precisely engineered for exact OEM fitment.

The result? Premium parts that improve both performance and appearance, trusted by those who demand nothing less than excellence.

Knowledge + Innovation = The Scopione Advantage

We know carbon fiber can be complex. That’s why we created this Carbon Fiber Glossary — to explain essential terms, from pre-preg to weave patterns, in plain language. Whether you’re exploring your first upgrade or fine-tuning your build, we want you to make informed decisions with total confidence.

At Scopione, our focus is not only on delivering top-tier products, but also on building a community that values innovation, education, and performance.

Upgrade with ScopioneCarbon

Whether your goal is to shave weight, boost performance, or elevate style, ScopioneCarbon is your trusted source for premium carbon fiber automotive and motorcycle parts.

Explore our collection today — experience the craftsmanship, durability, and innovation that set Scopione apart.

What Is Carbon Fiber and Why It Matters in Automotive Performance

Once reserved for aerospace due to its high cost, carbon fiber has become one of today’s most sought-after performance materials. From motorsports and supercars to wind energy and sporting goods, it is valued for being both extremely strong and exceptionally lightweight. This unique balance makes carbon fiber an ideal replacement for traditional materials like steel, aluminum, or plastic in high-end applications — especially where speed, precision, and durability are critical.

At its core, carbon fiber is made from ultra-thin strands of carbon, spun and woven into fabrics, then bonded together with high-strength resins. When cured under heat and pressure, the result is a composite material with an extraordinary strength-to-weight ratio, perfect for building lightweight yet reliable components.

How Carbon Fiber Is Made: From Fibers to High-Strength Composites

Carbon fibers are derived from base materials such as polyacrylonitrile (PAN) fibers or pitch, both of which are processed at extremely high temperatures. The result is thousands of carbon filaments bundled into threads, then woven into a cloth-like fabric.

When this fabric is combined with epoxy resins and cured, it transforms into a rigid, durable structure. Compared to steel, carbon fiber offers:

- Up to 10x the strength by weight

- Around 75% less weight for comparable parts

- Superior resistance to deformation and fatigue

- Better efficiency, handling, and performance in vehicles

This is why ScopioneCarbon parts don’t just look premium — they are engineered to perform at the highest level. Explore our precision-fit upgrades for the Lamborghini Aventador, Audi R8, and Ferrari 488 to see how carbon fiber transforms both performance and style.

Understanding “Grade A” Carbon Fiber

The term “Grade A” carbon fiber is often used in the market, but it is not an official industry standard. Instead, it’s a marketing label intended to signal high quality. At Scopione, we take quality far beyond labels.

We source our carbon fiber from Toray Industries, Inc., the global leader in advanced composites and the supplier trusted by top automakers worldwide. By using Toray pre-preg dry carbon sheets and proven epoxy formulas, we ensure every part we produce delivers:

- Motorsport-level durability

- Precise OEM fitment

- UV-resistant finishes for long-lasting shine

- The performance and reliability enthusiasts expect from a premium aftermarket upgrade

When you choose Scopione, you’re not just buying “Grade A” carbon — you’re investing in true aerospace-inspired engineering for the street and track.

Learn in-depth about Why Is Carbon Fiber So Expensive? Is It Worth the Cost? here:

- Why Does Carbon Fiber Cost So Much?

- Is Carbon Fiber Worth the Cost?

- When Is Carbon Fiber NOT Worth It?

Wet vs Dry Carbon Fiber: Key Differences Explained

Understanding the difference between dry and wet carbon fiber is crucial when selecting the right materials for your project. These two processes result in distinct differences in strength, weight, and cost. Below, we break down the pros and cons of each to help you make an informed decision.

What is Dry Carbon Fiber and Why It’s the Top Choice?

Dry carbon fiber uses pre-impregnated resin (pre-preg), which is sealed into a vacuum mold for curing. This process creates a stronger, lighter, and more durable product, perfect for performance applications like high-end automotive parts.

Advantages:

- Up to 60% lighter than wet carbon fiber

- Stronger and more durable

- Fewer imperfections and a matte finish

Disadvantages:

- Expensive (3–4 times more costly than wet carbon fiber)

- Requires a UV-protective clear coat for longevity

Understanding Wet Carbon Fiber: Cost-Effective but Less Durable

Wet carbon fiber is made by manually applying resin over dry carbon fabric. While the process is more affordable, it can result in heavier parts with air pockets, making it less durable than dry carbon.

Advantages:

- Affordable for more budget-conscious builds

- Glossy finish for aesthetic appeal

Disadvantages:

- Heavier and weaker than dry carbon

- Prone to imperfections like air pockets and uneven weaves

What is Pre-preg Carbon Fiber?

Pre-preg carbon fiber is the premium choice for high-performance parts. Made with pre-impregnated resin, it undergoes a high-pressure curing process to eliminate imperfections and create lightweight, strong components.

Key Differences at a Glance

| Feature | Dry (Pre-preg) | Wet |

|---|---|---|

| Weight | Lighter | Heavier |

| Strength | Stronger | Weaker |

| Cost | Expensive | Affordable |

| Appearance | Matte | Glossy |

| Consistency | Minimal imperfections | Air pockets |

If performance, weight reduction, and strength are critical, dry carbon fiber is your best choice. But if budget is your primary concern and you’re looking for an attractive glossy finish, wet carbon fiber may be the right option.

What Is a Carbon Fiber Weave?

The term “weave” refers to the pattern formed when carbon fiber strands, called tows, are woven into a fabric. Each weave style affects not only the look of the finished part but also its strength, flexibility, and best applications. Knowing the differences helps you choose the right material for both performance and appearance.

Plain Weave: Stable and Balanced

Plain weave carbon fiber has a checkerboard-style pattern created by an over-under weaving technique. Its short interlace distance makes it highly stable, helping the fabric maintain its shape and fiber orientation.

Advantages of Plain Weave:

- Stable structure that resists distortion

- Ideal for flat sheets, tubes, and simple 2D curves

- Balanced, symmetrical appearance

Limitations of Plain Weave:

- Less flexible for complex curves

- Sharp crimps at interlace points may create stress concentrations in high-stress applications

Plain weave is best when strength and stability matter more than aesthetics, often used for structural components and flat panels.

Twill Weave: Flexible and Stylish

Twill weave is more pliable and versatile, allowing it to conform to complex contours while maintaining good strength. Its distinctive diagonal “twill line” pattern makes it one of the most recognizable and visually appealing carbon weaves.

- 2×2 Twill: Each tow passes over two and under two — the most common weave in automotive applications

- 4×4 Twill: Each tow passes over four and under four, producing a looser weave

Advantages of Twill Weave:

- More flexible than plain weave, ideal for complex shapes

- Fewer crimps, reducing stress points

- Distinctive diagonal pattern popular in automotive styling

- Balanced mix of strength and aesthetics

Because of its premium look, 2×2 twill weave is widely used in visible parts such as hoods, diffusers, spoilers, and interior trims. It has become the signature weave in high-end applications across the automotive and aerospace industries.

How to Choose the Right Carbon Fiber Weave

Choosing the right weave depends on your goals:

- Choose Plain Weave if:

- You need stability for flat or simple shapes

- Structural integrity is more important than flexibility

- Choose Twill Weave if:

- You want versatility for curved, complex parts

- You value both strength and premium aesthetics

At Scopione, most high-visibility carbon fiber upgrades — like Lamborghini Huracan diffusers, McLaren 570S intake vents, and Ferrari 458 engine covers — are crafted in the iconic 2×2 twill weave for the perfect balance of performance and style.

1×1 vs 2×2 Carbon Fiber Weave: What’s the Difference?

When choosing carbon fiber parts, you’ll often see 1×1 and 2×2 weave patterns. The difference lies in the weave style:

- 1×1 weave → Checkerboard pattern, uniform and stable

- 2×2 weave → Diagonal pattern, more flexible and premium-looking

Both are lightweight, durable, and popular in automotive and aerospace use, but each has strengths depending on your project.

1×1 Weave: Stable and Checkerboard Pattern

The 1×1 weave uses a tight, symmetrical checkerboard layout. It offers excellent stability and a clean, OEM-style look.

Advantages:

- ✅ Strong and stable, resists distortion

- ✅ Affordable due to simpler weaving process

- ✅ Clean checkerboard appearance

Limitations:

- ❌ Less flexible, harder to mold over complex curves

- ❌ Limited adaptability for intricate contours

Applications:

Ideal for flat or gently curved parts such as roof panels (e.g., BMW M3 roofs) or structural-grade components where rigidity matters most.

2×2 Weave: Flexible and Diagonal Pattern

The 2×2 weave is the most widely used in automotive aftermarket upgrades. Its diagonal “twill line” pattern gives parts a stylish, high-end finish while allowing greater flexibility during production.

Advantages:

- ✅ More pliable, fits complex curves and angles

- ✅ Fewer crimps = fewer weak points

- ✅ Distinctive diagonal look popular in supercars & aftermarket parts

Limitations:

- ❌ Slightly less stable than 1×1

- ❌ Higher cost due to more complex manufacturing

Applications:

The preferred weave for visible performance upgrades, such as:

- Lamborghini Gallardo dash trims & engine covers

- Nissan GTR R35 air vents & wheel covers

- Maserati GranTurismo splitters & mirror covers

Side-by-Side Comparison

| Feature | 1×1 Weave | 2×2 Weave |

|---|---|---|

| Pattern | Checkerboard | Diagonal (twill line) |

| Flexibility | Low – best for simple shapes | High – conforms to complex curves |

| Stability | Very stable, resists distortion | Slightly less stable |

| Cost | More affordable | Higher due to complexity |

| Appearance | Clean, OEM style | Premium, stylish, most recognizable |

Other Weave Patterns

While 1×1 and 2×2 are the most common, other weaves exist:

- Satin (4-, 5-, 8-harness): Increasing flexibility and smoother finishes

- Unidirectional: Strength in one direction for structural components

- Triaxial: Multi-directional reinforcement for durability

- 4×4 weave: Balanced compromise between strength and flexibility

Which Carbon Fiber Weave Should You Choose?

- Choose 1×1 for flat panels, roofs, or structural parts where strength and uniformity are key.

- Choose 2×2 for visible, complex, or curved parts where both style and performance matter.

At Scopione, we specialize in 2×2 twill weave for most aftermarket upgrades because it delivers the perfect balance of strength, flexibility, and iconic style.

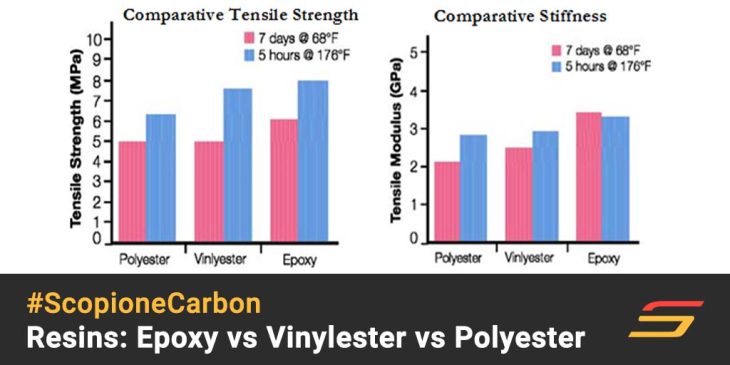

Epoxy vs Vinylester vs Polyester Resins in Carbon Fiber Parts

When evaluating carbon fiber parts, it’s not just the weave that matters — the resin system plays an equally important role. The resin binds the fibers together, determines durability, and affects cost. The three most common resin types in automotive carbon fiber applications are epoxy, vinylester, and polyester.

Understanding their strengths and limitations ensures you choose parts that deliver the right balance of performance, appearance, and value.

Epoxy Resin: Strongest and Most Durable

Epoxy resin is the gold standard for carbon fiber parts. It provides the highest strength, stiffness, and resistance to fatigue.

Advantages:

- ✅ Strongest & most durable (highest tensile strength)

- ✅ Best adhesion to carbon fiber, Kevlar, and fiberglass

- ✅ Superior resistance to water, chemicals, and osmosis

- ✅ Available in specialized formulations for heat or performance needs

Limitations:

- ❌ Higher cost compared to vinylester or polyester

- ❌ UV sensitivity (can yellow without UV-protected finishes)

- ❌ May form amine blush (a waxy film during curing that must be cleaned)

Scopione Standard:

At Scopione, we use epoxy resins with built-in UV protection, ensuring your parts maintain both strength and appearance for years to come.

Vinylester Resin: Balanced but Less Strong

Vinylester resin is moderately strong — about one-third as strong as epoxy — but offers certain cosmetic and practical benefits.

Advantages:

- ✅ More affordable than epoxy

- ✅ Better adhesion to fiberglass than polyester

- ✅ Often used for surface finishes to enhance appearance

Limitations:

- ❌ Weaker bond with carbon fiber & Kevlar

- ❌ Lower strength and durability compared to epoxy

Use Case:

Best for cosmetic parts or coatings where appearance matters more than structural performance.

Polyester Resin: Lowest Cost, Lowest Strength

Polyester resin is the least expensive but also the least effective when it comes to carbon fiber. It bonds poorly to carbon fiber and Kevlar, though it is widely used with fiberglass.

Advantages:

- ✅ Very low cost

- ✅ Works acceptably with fiberglass

Limitations:

- ❌ Weak bonding to carbon fiber and Kevlar

- ❌ Poor strength and durability for automotive applications

- ❌ Not recommended for performance-grade parts

Use Case:

Suitable only for fiberglass-based components where cost savings matter more than performance.

Side-by-Side Comparison

| Resin Type | Strength & Durability | Bonding Quality | Cost | Best Use Case |

|---|---|---|---|---|

| Epoxy | ⭐⭐⭐⭐⭐ Highest | Excellent with CF/Kevlar/Fiberglass | $$$ | High-performance carbon fiber parts |

| Vinylester | ⭐⭐ Moderate | Fair with CF, strong with fiberglass | $$ | Cosmetic finishes, fiberglass blends |

| Polyester | ⭐ Lowest | Poor with CF/Kevlar, fair with fiberglass | $ | Fiberglass-only parts |

Which Resin Should You Choose?

- Choose Epoxy if you want maximum strength, durability, and premium performance.

- Choose Vinylester if you’re on a budget and value appearance over strength.

- Avoid Polyester for critical carbon fiber components — it’s only viable for low-cost fiberglass builds.

ScopioneCarbon Advantage: All our premium carbon fiber upgrades use epoxy resin systems from world-class suppliers, ensuring superior bonding strength, UV resistance, and long-lasting performance compared to cheaper alternatives.

Back to top ↑Carbon Fiber Surface Treatments & Finishes Explained

The surface treatment or finish of a carbon fiber part affects not only its appearance, but also its durability, UV protection, and handling performance. Choosing the right finish ensures you get the balance of style, strength, and maintenance that fits your needs.

Appearance Finishes

Glossy Finish

- Appearance: High-gloss, mirror-like surface that highlights the carbon fiber weave.

- Advantages: Maximum depth and visual appeal; popular in luxury and show applications.

- Best For: Hoods, spoilers, and aero accents where a striking look matters most.

- Considerations: Shows fingerprints and scratches more easily; requires care.

Matte Finish

- Appearance: Subdued, non-reflective surface with weave still visible.

- Advantages: Conceals scratches and fingerprints; sleek, modern look.

- Best For: Trim pieces, interior accents, or frequently handled parts.

Satin Finish

- Appearance: Balanced, soft sheen between gloss and matte.

- Advantages: Refined look with reduced reflectivity; versatile and durable.

- Best For: Versatile applications where both style and practicality matter.

Painted Finish

- Appearance: Opaque color applied over the carbon fiber, hiding the weave.

- Advantages: Unlimited customization; extra environmental protection.

- Best For: Custom builds, color-matched accents, and motorsport styling.

Performance Finishes

Clearcoat Finish

- Appearance: Transparent gloss or matte layer.

- Advantages: Adds UV protection, durability, and depth.

- Best For: Outdoor-exposed parts — such as Lamborghini Aventador diffusers and Audi R8 hoods.

Textured / Peel-Ply Finish

- Appearance: Rough, sandpaper-like surface.

- Advantages: Excellent for bonding adhesives or layering.

- Best For: Structural or hidden components.

Sanded Finish

- Appearance: Smooth, matte surface achieved by sanding outer resin.

- Advantages: Removes imperfections; ready for paint or additional coatings.

- Best For: Prep stages before painting or secondary finishing.

Specialty Finishes

Forged Carbon Finish

- Appearance: Unique marbled pattern created by randomly arranged carbon fiber fragments.

- Advantages: Eye-catching, exclusive, associated with high-end supercars.

- Best For: Luxury upgrades, like Bentley Continental GT trims or special-edition components.

Choosing the Right Finish

- Glossy: Best for visual impact on show cars and aero parts.

- Matte/Satin: Durable and practical for everyday use or frequently handled parts.

- Forged Carbon: Unique, luxury look to stand out from traditional weaves.

- Performance Finishes (Clearcoat, Textured, Sanded): For protection, prep, or hidden structural components.

- Painted: For full customization and color-matched builds.

ScopioneCarbon Advantage: All our premium carbon fiber parts feature UV-protected clearcoats to ensure long-lasting durability, while select components are available in glossy, satin, matte, or forged finishes — giving you both performance and style.

Advantages of Carbon Fiber in Cars & Performance Upgrades

Carbon fiber isn’t just lightweight — it’s a revolution in automotive engineering. By combining strength, flexibility, and style, it delivers benefits far beyond traditional materials like steel or aluminum. Here’s why ScopioneCarbon parts set the standard for performance enthusiasts worldwide:

1. Weight Reduction & Efficiency

- Up to 75% lighter than steel and 50% lighter than aluminum

- Improves fuel efficiency and extends EV driving range

- Lower weight = faster lap times, better acceleration, and more agile cornering

2. Strength & Durability

- Exceptional strength-to-weight ratio (up to 10x stronger than steel by weight)

- Corrosion-proof — carbon fiber won’t rust or oxidize

- Long-lasting durability with UV-protected clearcoats (standard in Scopione parts)

3. Performance & Handling

- Reduced mass improves braking responsiveness

- Enhances maneuverability and steering precision

- Trusted in motorsports for delivering consistent high-speed stability

4. Design Flexibility & Aesthetics

- Can be molded into complex aerodynamic shapes

- Iconic 1×1 and 2×2 weave patterns showcase racing heritage

- Available in gloss, matte, satin, or forged finishes for a premium look

5. Thermal Stability & Safety

- Maintains structural integrity under extreme heat (engine bays, brakes, exhaust surrounds)

- Can absorb and dissipate impact energy, improving crash safety

- Preferred material in supercar monocoques and aerospace engineering

6. Sustainability & Environmental Benefits

- Lighter vehicles = reduced emissions over their lifetime

- Recycling technologies now enable carbon fiber re-use

- Aligns with modern demand for eco-friendly, high-performance engineering

Why Choose ScopioneCarbon?

At Scopione, every part is engineered with Toray pre-preg carbon fiber sheets and epoxy resin systems with UV protection, ensuring long-lasting strength, finish, and fitment.

That’s why owners of the many exotic car models trust ScopioneCarbon upgrades to deliver both performance and aesthetics.

Upgrade today and experience the unmatched strength, style, and innovation of ScopioneCarbon parts.

I. Carbon Fiber Basics

Understanding the fundamentals of carbon fiber begins with its core structure — the individual filaments, bundles, and layers that form every component. This section introduces key concepts such as tows, plies, and weaves, explaining how fiber orientation and pattern determine the appearance, flexibility, and strength of each Scopione carbon fiber part. These are the essential building blocks that define the foundation of all composite materials.

Tow (Strand / Roving)

- Definition: A tow is a bundle of thousands of carbon fiber filaments packaged on a spool (also called “strand” or “roving”). For example, a 3K tow contains 3,000 fibers.

- Why It Matters: Tow size determines the weave pattern, flexibility, and appearance of carbon fiber parts.

- Example: Smaller tows (3K, 6K) give a fine, cosmetic look for interior trims, while larger tows (12K–24K) are stronger and often used in large body panels like hoods or diffusers.

Filament

- Definition: A single, ultra-thin strand of carbon fiber — about 5–10 microns in diameter (much thinner than a human hair).

- Why It Matters: Bundled filaments form tows, which create fabrics for composites. The strength of each filament contributes to the overall performance of the material.

- Example: Every ScopioneCarbon panel is made from millions of these filaments, aligned to maximize tensile strength and durability.

Ply

- Definition: A ply is a single layer of carbon fiber fabric.

- Why It Matters: Engineers stack multiple plies in different orientations to achieve strength in multiple directions.

- Example: A Scopione diffuser might have several plies — some oriented at 0° for lengthwise strength, others at 90° or 45° for shear resistance.

Laminate

- Definition: A laminate is the final structure created by stacking multiple plies together.

- Why It Matters: The performance of a laminate depends on fiber orientation, resin type, and curing process.

- Example: Premium laminates made with pre-preg epoxy carbon fiber (like those used in Scopione parts) are stronger and lighter than wet-layup alternatives.

Matrix

- Definition: The matrix is the resin system (epoxy, vinylester, or polyester) that binds carbon fibers together.

- Why It Matters: While weaker than the fibers themselves, the matrix distributes loads, protects against moisture, and ensures durability.

- Example: Scopione exclusively uses epoxy resin systems with UV protection to maximize part longevity and appearance.

Fiber Orientation

- Definition: Fiber orientation describes the direction in which carbon fibers are aligned within each ply.

- Why It Matters: The angle and pattern of the fibers directly influence how a part handles stress, impact, and bending.

- Example: 0° fibers increase longitudinal stiffness, while ±45° orientations enhance shear resistance — both crucial for balanced ScopioneCarbon performance parts.

Cross-Ply

- Definition: Cross-ply construction refers to layers of carbon fiber arranged at alternating angles, typically 0° and 90°.

- Why It Matters: Alternating directions distribute loads evenly and reduce weak points, improving structural integrity.

- Example: Scopione spoilers and diffusers use cross-ply layouts to maintain rigidity while absorbing aerodynamic forces efficiently.

Biaxial Weave

- Definition: A biaxial weave consists of two layers of fibers oriented in two directions (commonly 0° and 90°).

- Why It Matters: It provides balanced strength in both lengthwise and crosswise directions, ideal for parts requiring stiffness and minimal weight.

- Example: Many Scopione body panels use biaxial carbon for optimal load balance and reduced flex under pressure.

Triaxial Weave

- Definition: A triaxial weave incorporates fibers oriented in three directions — typically 0°, +60°, and –60°.

- Why It Matters: This three-axis design enhances torsional rigidity and impact distribution, making it suitable for high-performance applications.

- Example: Triaxial weaves are used in motorsport-grade Scopione components, where multidirectional stress resistance is vital.

Unidirectional (UD) Carbon Fiber

- Definition: In unidirectional fiber, all carbon strands run parallel in a single direction.

- Why It Matters: It offers extremely high strength and stiffness along one axis but less resistance in other directions, requiring strategic layering.

- Example: Scopione aerodynamic parts often integrate UD layers to reinforce load paths along airflow or stress zones.

Isotropic vs. Anisotropic

- Definition: Isotropic materials have equal properties in all directions; anisotropic materials (like carbon fiber) vary depending on fiber orientation.

- Why It Matters: Carbon fiber’s anisotropy allows engineers to optimize strength exactly where it’s needed — something metals cannot achieve.

- Example: A Scopione carbon splitter may be anisotropically designed — ultra-rigid front-to-back, yet slightly flexible side-to-side for impact absorption.

In Summary: These core elements — tows, weaves, and fiber orientations — define every ScopioneCarbon part’s strength, weight, and appearance.

II. Carbon Fiber Manufacturing Processes

The quality of carbon fiber parts depends heavily on the manufacturing methods used to shape, bond, and cure the materials. Here, we explore advanced processes such as autoclave curing, prepreg layup, and wet layup, along with supporting techniques like debulking, post-curing, and mold preparation. Each process plays a crucial role in ensuring that Scopione components achieve optimal strength, precision fitment, and long-term durability.

Autoclave Process

- Definition: An autoclave is a high-pressure, high-temperature oven used to cure pre-preg carbon fiber parts.

- Why It Matters: This process ensures even resin distribution, removes air pockets, and produces the highest-quality, aerospace-grade composites.

- Example: Scopione uses autoclave curing to create lightweight, strong, and pinhole-free parts for supercars like the Lamborghini Huracan and Ferrari 458.

Debulking

- Definition: Debulking is a process that removes trapped air and compacts layers of carbon fiber during layup by applying vacuum pressure between layers.

- Why It Matters: It prevents voids and delamination, ensuring that multiple plies bond tightly and uniformly before final curing.

- Example: Scopione performs intermediate debulking during multi-layer layups to guarantee a flawless weave and void-free structure in each part.

Carbonization

- Definition: The process of heating stabilized precursor fibers (like PAN) to 1200–1500°C, removing non-carbon elements and leaving pure carbon.

- Why It Matters: Carbonization gives the fibers their incredible strength and stiffness, turning them into true carbon fiber.

- Example: Without carbonization, the material wouldn’t achieve the strength-to-weight ratio that makes Scopione upgrades superior to steel or aluminum alternatives.

Wet Layup

- Definition: A traditional process where dry carbon fabric is placed into a mold and then manually coated with resin before curing.

- Why It Matters: While cost-effective, wet layup often results in heavier, less precise parts with more risk of air bubbles.

- Example: Many cheap aftermarket parts use wet layup, but Scopione avoids it to ensure consistent quality and performance.

How Precursors For Carbon Fiber Polyacrylonitrile (PAN) Is Created?

Prepreg (Pre-Impregnated)

- Definition: Carbon fiber fabric that has already been impregnated with a precise amount of resin, ready for autoclave curing.

- Why It Matters: Prepreg guarantees perfect fiber-to-resin ratios, higher strength, and lighter weight compared to wet layup.

- Example: Scopione’s R8 hoods and Aventador spoilers are made from Toray prepreg sheets, ensuring flawless weave alignment and durability.

Compression Molding

- Definition: A high-pressure molding process where carbon fiber prepreg sheets are placed into a heated mold and compressed to form a rigid part.

- Why It Matters: It allows rapid production of strong, uniform components while maintaining precise dimensional tolerances.

- Example: Scopione uses compression molding for smaller, complex parts like mirror caps and interior trims to achieve consistent shapes and high surface finish quality.

Tooling / Mold Surface

- Definition: Tooling refers to the mold or surface used to form carbon fiber parts. These are typically made of aluminum, steel, or carbon fiber-reinforced epoxy.

- Why It Matters: The surface quality and temperature stability of the mold directly affect the final product’s dimensional accuracy and finish.

- Example: Scopione’s molds are CNC-machined to micron-level precision, ensuring each Lamborghini, Ferrari, or Audi component fits perfectly and requires no post-adjustment.

Cure Cycle

- Definition: The specific temperature, pressure, and time schedule used to cure composites.

- Why It Matters: Precise cure cycles determine whether a part achieves its full strength, stiffness, and finish quality.

- Example: Scopione follows aerospace-grade cure cycles to ensure each component is fully hardened and resistant to stress, heat, and UV exposure.

Curing Cycle (Alternate or Expanded Term)

- Definition: The entire heating and cooling profile applied during resin polymerization. It includes ramp-up, dwell (hold), and cool-down stages under vacuum or pressure.

- Why It Matters: Optimizing the curing cycle prevents resin brittleness, uneven hardening, or warping — all of which affect long-term durability.

- Example: Scopione’s precision-controlled curing cycles ensure uniform resin flow, crystal-clear finishes, and structural integrity across every part.

Post-Curing

- Definition: A secondary heat treatment applied after initial curing to further strengthen the resin matrix and improve thermal resistance.

- Why It Matters: Enhances the material’s dimensional stability, chemical resistance, and load-bearing performance at high temperatures.

- Example: Post-curing helps Scopione components maintain their shape and rigidity even under extreme engine-bay heat or prolonged sun exposure.

In Summary: Through these precision manufacturing processes, Scopione transforms raw carbon fiber into lightweight, aerospace-grade automotive components built for performance and longevity.

III. Carbon Fiber Material Properties

Every carbon fiber component’s performance is defined by its material properties — strength, stiffness, flexibility, and resistance to environmental stress. This section details critical engineering terms such as tensile strength, shear strength, interlaminar shear, fatigue resistance, and coefficient of thermal expansion (CTE). Understanding these properties helps you evaluate how Scopione’s products outperform traditional materials like steel or aluminum in both weight and endurance.

Tensile Strength

- Definition: The maximum pulling force a material can withstand before breaking.

- Why It Matters: Carbon fiber has exceptionally high tensile strength, far exceeding steel by weight.

- Example: Scopione parts maintain integrity under extreme loads, making them ideal for splitters, diffusers, and aero components that experience high tension forces.

Shear Strength

- Definition: A material’s ability to resist sliding forces along a plane.

- Why It Matters: In composites, shear strength is critical where layers (plies) meet. Weak shear strength can cause layers to separate.

- Example: Premium Scopione laminates are engineered to resist delamination, ensuring long-term structural stability.

Modulus (Stiffness)

- Definition: The ratio of stress to strain — a measure of a material’s stiffness.

- Why It Matters: A higher modulus means less bending under load, which is vital in high-performance automotive parts.

- Example: Scopione carbon fiber panels use high-modulus fibers, giving parts like hoods and roofs the rigidity to perform at high speeds without flex.

Fatigue Resistance

- Definition: A material’s ability to withstand repeated cycles of stress without failure.

- Why It Matters: Automotive and motorsport parts are constantly exposed to vibration and stress — poor fatigue resistance leads to cracking.

- Example: ScopioneCarbon parts offer excellent fatigue resistance, ensuring durability even under track-level demands.

Void Content

- Definition: The percentage of air pockets within a composite.

- Why It Matters: Higher void content weakens the structure, reduces strength, and can cause premature failure.

- Example: Cheap aftermarket parts often have high void content from poor curing, while Scopione’s autoclave process eliminates voids, guaranteeing maximum strength.

Electrical Conductivity

- Definition: A measure of how well a material conducts electricity. Carbon fiber is conductive, unlike fiberglass.

- Why It Matters: This property can be both an advantage (grounding, static discharge) and a concern (galvanic corrosion near metals).

- Example: In aerospace and motorsports, electrical conductivity is carefully managed — and ScopioneCarbon parts are engineered with protective coatings to prevent issues.

Interlaminar Shear Strength (ILSS)

- Definition: The ability of a composite material to resist sliding between its layers.

- Why It Matters: High ILSS prevents delamination and ensures the laminate behaves as a single, strong unit under load.

- Example: Scopione’s advanced curing methods maximize ILSS, keeping multi-layer parts like rear diffusers structurally cohesive even under aerodynamic pressure.

Impact Resistance

- Definition: The ability of a material to absorb and dissipate energy from sudden impacts without cracking or fracturing.

- Why It Matters: Essential for parts exposed to road debris or track use, where impacts are common.

- Example: Scopione parts use multi-directional layups that enhance impact resistance, protecting against chips, cracks, and stone strikes.

Coefficient of Thermal Expansion (CTE)

- Definition: The rate at which a material expands or contracts with temperature changes.

- Why It Matters: Low CTE means carbon fiber parts retain their shape under extreme heat — unlike metals that expand and distort.

- Example: Scopione carbon fiber engine covers maintain perfect alignment and fitment even under high-engine-bay temperatures.

Fiber Volume Fraction (FVF)

- Definition: The percentage of fiber relative to resin within a composite material.

- Why It Matters: Optimal FVF improves strength and stiffness; too much resin weakens the part, while too little resin can cause dry spots or delamination.

- Example: ScopioneCarbon components are precision-cured to maintain ideal FVF, ensuring consistent weight, strength, and finish quality.

Toughened Matrix

- Definition: A resin system modified with additives to improve toughness and crack resistance.

- Why It Matters: Reduces brittleness and enhances a part’s ability to absorb energy under stress.

- Example: Scopione uses toughened epoxy matrices in high-stress parts such as front splitters and spoilers to improve flexibility without sacrificing rigidity.

Sandwich Structure

- Definition: A lightweight structural design consisting of two strong outer layers (skins) bonded to a lightweight core material (like foam or honeycomb).

- Why It Matters: Increases stiffness-to-weight ratio and impact resistance while minimizing overall weight.

- Example: Scopione roof panels and underbody trays use sandwich construction for maximum strength and minimal mass.

Core Material

- Definition: The inner layer within a sandwich structure, made from lightweight materials like Nomex honeycomb or structural foam.

- Why It Matters: The core adds thickness and stiffness without significantly increasing weight.

- Example: Scopione’s multi-layer carbon panels incorporate structural foam cores to absorb vibration and resist flex at high speeds.

Viscoelasticity

- Definition: The property of a material that exhibits both viscous and elastic behavior when deformed.

- Why It Matters: Determines how a material responds to long-term stress, vibration, and temperature — important in parts exposed to sustained loads.

- Example: Scopione’s resin systems are engineered with optimized viscoelastic properties to resist vibration-induced deformation in high-speed applications.

Dimensional Tolerance

- Definition: The allowable variation in a part’s dimensions during manufacturing.

- Why It Matters: Tight tolerances ensure consistent fitment, aerodynamics, and compatibility across all installations.

- Example: Every Scopione part is laser-verified for dimensional accuracy, guaranteeing perfect fitment out of the box.

Nondestructive Testing (NDT)

- Definition: Inspection methods used to evaluate material quality without causing damage, such as ultrasound, X-ray, or thermography.

- Why It Matters: Ensures structural integrity and detects voids or delamination before parts reach customers.

- Example: Scopione applies aerospace-grade inspection standards to verify the quality of every major structural component.

In Summary: These properties illustrate why ScopioneCarbon composites outperform metal alternatives—combining strength, flexibility, and precision at a fraction of the weight.

IV. Carbon Fiber Design & Structure

In carbon fiber engineering, structural design and layering dictate a part’s performance, strength, and visual symmetry. This section focuses on how precise layering sequences and quality bonding prevent structural weaknesses. Every Scopione component is engineered with aerospace-level precision — from its internal ply arrangement to its reinforced bonding — ensuring each product maintains its strength, stability, and flawless appearance over time.

Layup Schedule

- Definition: The specific plan for how many plies are used, in what orientations, and in what order.

- Why It Matters: A precise layup schedule ensures consistent performance and quality across every part.

- Example: Scopione follows aerospace-grade layup schedules, guaranteeing predictable strength and fitment.

Delamination

- Definition: When layers of a composite separate due to defects, impacts, or poor bonding.

- Why It Matters: Delamination weakens the part and can lead to failure under stress.

- Example: Cheap wet-layup parts often delaminate over time. Scopione’s autoclave-cured laminates are built to resist separation for maximum safety and longevity.

In Summary: Meticulous design and flawless bonding ensure every Scopione part maintains its aerodynamic integrity, dimensional precision, and long-term strength.

V. Carbon Fiber Chemistry & Raw Materials

At the molecular level, carbon fiber is a result of advanced chemistry and thermal transformation. This section covers the essential materials — PAN precursors, resins, nanoresins, and thermoset polymers — as well as processes like oxidation, carbonization, and stabilization. By understanding these chemical foundations, you’ll gain insight into why Scopione relies on world-class raw materials and controlled curing systems to achieve superior quality and longevity in every part.

PAN (Polyacrylonitrile)

- Definition: The most common raw material (precursor) used to create carbon fiber.

- Why It Matters: PAN-based carbon fibers offer exceptional tensile strength and balanced performance, making them ideal for structural automotive parts.

- Example: Scopione parts use Toray PAN-based prepreg carbon sheets, trusted in aerospace and motorsports for unmatched quality.

Precursor

- Definition: The base material from which carbon fibers are made (typically PAN or pitch).

- Why It Matters: The choice of precursor affects strength, stiffness, and cost of the final carbon fiber. PAN produces strong, versatile fibers, while pitch yields ultra-high modulus fibers but at higher cost.

- Example: Scopione relies on PAN precursors for performance car parts, balancing strength and affordability.

Resin

- Definition: The polymer matrix that binds carbon fibers together and gives the part its final shape.

- Why It Matters: The resin determines durability, flexibility, and resistance to UV or chemicals. Common types include epoxy, vinylester, and polyester.

- Example: Scopione exclusively uses epoxy resin with UV protection for maximum bonding strength and long-lasting finishes.

Nanoresins

- Definition: Advanced epoxy or polymer resins infused with nanoparticles to enhance mechanical and thermal performance.

- Why It Matters: Nanoresins improve toughness, crack resistance, and heat stability without increasing weight — ideal for high-stress applications.

- Example: Scopione incorporates nanoresin-enhanced composites in select products to deliver exceptional impact resistance and long-term durability.

Gel Coat

- Definition: A thin outer layer of specially formulated resin applied to the surface of a composite part to enhance appearance and environmental protection.

- Why It Matters: The gel coat provides a smooth, glossy finish and acts as a barrier against moisture, UV light, and minor abrasion.

- Example: Select Scopione parts use high-clarity UV-stable gel coats for a mirror-like gloss that accentuates the carbon weave beneath.

Thermoset vs. Thermoplastic

- Definition:

- Thermoset resins (e.g., epoxy): Harden permanently when cured, delivering high stiffness and strength.

- Thermoplastics: Can be reheated and reshaped multiple times, offering flexibility but usually less stiffness.

- Why It Matters: Thermosets dominate in aerospace and automotive because of their superior strength and stability.

- Example: ScopioneCarbon parts are built with thermoset epoxy systems, ensuring rigidity and long-term durability at high speeds.

Oxidation / Stabilization

- Definition: A critical thermal process in which PAN precursor fibers are heated in air at moderate temperatures (around 200 – 300 °C). During this stage, the polymer chains chemically react with oxygen, forming a cross-linked structure that becomes thermally stable. This ensures the fibers maintain their shape during the next high-temperature carbonization step.

- Why It Matters: Stabilization transforms the raw PAN into an infusible material capable of withstanding the extreme heat used in carbonization. Without this process, the fibers would melt or deform, compromising the uniformity and strength of the final carbon fiber.

- Example: Scopione ensures each batch of PAN precursor undergoes precise stabilization cycles in a controlled-atmosphere furnace, producing fibers that retain their dimensional integrity and form the foundation for high-strength Toray-grade carbon sheets.

In Summary: The chemistry behind ScopioneCarbon begins with advanced PAN precursors and epoxy resin systems, strengthened by nanoresins and stabilized through controlled oxidation. This scientific foundation ensures every Scopione component achieves aerospace-grade strength, lightweight precision, and long-term durability.

Frequently Asked Questions (FAQs)

I. Performance & Benefits

Q: What are the benefits of carbon fiber in cars?

A: Carbon fiber is prized for its lightweight strength. Compared to steel or aluminum, it delivers:

- Faster acceleration and improved braking.

- Better handling and agility from reduced vehicle mass.

- Superior aesthetics with its distinctive weave.

Q: How does carbon fiber compare to steel or aluminum?

A: Carbon fiber provides similar or greater strength at a fraction of the weight. Unlike metals, it is corrosion-resistant and can be molded into complex aerodynamic shapes, making it ideal for performance parts.

Q: Do carbon fiber parts affect vehicle safety?

A: High-quality, properly installed carbon fiber parts are safe and often used in motorsports. ScopioneCarbon parts are engineered for OEM-level fitment and undergo strict quality control for strength, reliability, and safety.

Q: Is carbon fiber resistant to corrosion?

A: Yes. Unlike metals, carbon fiber does not rust, making it ideal for parts exposed to rain, heat, and road debris.

II. Manufacturing & Options

Q: What is the difference between dry (pre-preg) and wet carbon fiber?

A:

- Dry Carbon Fiber (Pre-preg): Resin is pre-applied with precise control, then cured in an autoclave. Results in parts that are lighter, stronger, and premium quality.

- Wet Carbon Fiber: Resin is applied by hand before curing. More affordable, but parts are heavier and less consistent.

Scopione exclusively uses Toray pre-preg carbon fiber with autoclave curing for aerospace-grade results.

Q: Why do some carbon fiber parts have different weave patterns?

A: The weave affects appearance and flexibility during manufacturing:

- 1×1 Weave: Checkerboard look, very stable, best for flat surfaces.

- 2×2 Twill: Diagonal pattern, more flexible, better for complex curves.

Performance is nearly identical — the choice is mostly aesthetic preference.

Q: Are there color options for carbon fiber?

A: Traditional carbon fiber has a black/gray finish, but colored options exist. By adding pigments to the resin or using dyed fibers, Scopione can offer custom looks while maintaining strength.

III. Care & Maintenance

Q: How should I clean and maintain carbon fiber parts?

A:

- Wash with mild soap and water using a soft cloth.

- Avoid abrasive cleaners that can scratch clear coat.

- Apply a UV-protectant to prevent sun fading.

- Address chips or cracks quickly to preserve both strength and appearance.

Q: Can carbon fiber parts be repaired?

A: Minor scratches can often be polished. Structural damage requires professional repair to maintain integrity. Scopione recommends consulting experts for safety-critical components.

IV. Fitment & Compatibility

Q: How do I know if carbon fiber parts fit my vehicle?

A: Always confirm that parts are designed for your exact make, model, and year. ScopioneCarbon parts are engineered with OEM-level fitment, ensuring proper alignment and installation without modification.

V. Sustainability

Q: Is carbon fiber environmentally friendly?

A: Manufacturing carbon fiber is energy-intensive, but in vehicles it delivers long-term environmental benefits:

- Lower weight → improved fuel efficiency → reduced emissions.

- Increasing advancements in carbon fiber recycling are making parts more sustainable.

VI. Scopione-Specific FAQs (Trust & Authority)

Q: Why choose ScopioneCarbon parts over cheaper alternatives?

A: Unlike low-cost wet-layup parts, ScopioneCarbon uses Toray pre-preg materials cured in autoclaves, ensuring:

- Superior strength-to-weight ratio

- UV-protected epoxy finishes

- Perfect OEM fitment

- Motorsport-inspired durability

Q: Do ScopioneCarbon parts come with a warranty?

A: Yes. Every ScopioneCarbon component is backed by our quality guarantee, giving you confidence in durability, fitment, and finish.

Q: Can carbon fiber upgrades increase my car’s resale value?

A: Premium carbon fiber enhancements often boost resale value by appealing to performance buyers who value lightweight materials, aesthetics, and exclusivity.

Care and Maintenance of Carbon Fiber Parts

Proper Care = Lasting Performance

Every ScopioneCarbon component is engineered for long-term durability and performance. However, proper care ensures your investment maintains its structural integrity, glossy finish, and premium look for years to come.

1. Regular Cleaning (Every 2–4 Weeks)

- ✅ Use: A pH-neutral automotive shampoo or mild soap with a soft microfiber towel.

- 🚫 Avoid: Abrasive brushes, rough sponges, or household cleaners — they can dull or scratch the UV clear coat.

- 💧 Pro Tip: Rinse with filtered water and dry with a clean microfiber towel to avoid water spots and swirl marks.

- 🧼 Brand Note: Scopione’s UV-stable epoxy responds best to gentle, pH-neutral cleaning solutions.

2. UV Protection (Every 2–3 Months)

Even though every ScopioneCarbon part is coated with a UV-resistant epoxy, consistent protection enhances longevity.

- ☀️ Apply: A ceramic coating or high-quality carnauba wax with UV inhibitors.

- 🕶️ Park Smart: Whenever possible, park in shaded areas or use a breathable car cover.

- ✨ Result: Prevents oxidation, fading, and discoloration from prolonged sun exposure.

3. Routine Inspection & Damage Prevention (Monthly)

- 🔍 Inspect: Check for cracks, chips, or delamination — especially after spirited driving or track use.

- 🚫 Avoid: Contact with gasoline, brake fluid, or harsh solvents. If accidental exposure occurs, immediately rinse with mild soap and water.

- 🧰 Repair Tip: Minor chips can often be spot-treated, but structural damage should always be assessed by a ScopioneCarbon-certified specialist to maintain integrity.

4. Polishing & Restoration (As Needed)

- ✨ Light Polishing: Use a fine-grade, UV-safe carbon fiber polish with a soft foam pad to restore clarity.

- 🧴 Professional Restoration: For heavy oxidation or yellowing, have parts refinished with a UV-stable ceramic topcoat.

- 🔒 Seal It: Always reapply a ceramic or protective sealant afterward to maintain shine and protect from contaminants.

5. ScopioneCarbon Maintenance Checklist

Keep your carbon fiber parts performing and looking new:

- 🚿 Avoid high-pressure washers — they can cause resin delamination.

- 🌡️ Protect from extreme heat or cold; both can stress the epoxy matrix.

- 🧽 Clean and wax on schedule to preserve the original Scopione gloss.

- 🕒 Reapply ceramic or UV wax every 6 months for long-term surface protection.

6. Long-Term Preservation Tips

- 💡 Storage: If your vehicle will be parked for extended periods, keep it covered and away from direct heat sources.

- 🛡️ Clear Coat: Never sand or buff raw carbon fiber. Always maintain the clear-coated surface to protect structural layers underneath.

- 🚘 Driving Care: Avoid direct stone impact areas; use Scopione PPF (Paint Protection Film) or guards for front lips and diffusers when possible.

Final Tip

Proper maintenance not only enhances your car’s appearance but also extends the lifespan and performance of your ScopioneCarbon components.

For advanced restoration or ceramic coating recommendations, contact ScopioneCarbon Support — our experts can direct you to approved detailing partners experienced with high-performance carbon fiber finishes.

Summary: The ScopioneCarbon Standard

Precision. Innovation. Performance.

Congratulations — you now have a clear understanding of the core terminology and processes that define premium carbon fiber manufacturing. At ScopioneCarbon, we believe that knowledge builds confidence. That’s why we not only craft high-performance components — we also empower you to understand what sets them apart.

Our team of specialists is always available to guide you through every step — whether you’re exploring materials, comparing finishes, or seeking recommendations for your vehicle.

Customization Without Compromise

No two vehicles — or drivers — are the same. ScopioneCarbon proudly offers bespoke customization options, allowing you to personalize your components with:

- Exclusive finishes and weave patterns

- Tailored dimensions for perfect OEM-level fitment

- Specialized coatings for performance, UV resistance, or weight reduction

Our goal is to bring your vision to life while maintaining the precision and durability that define every Scopione part.

Driven by Research and Development

We continuously invest in cutting-edge technologies to keep ScopioneCarbon at the forefront of innovation.

Our engineers and craftsmen work side by side to develop next-generation carbon fiber composites, optimized for strength, weight savings, and visual perfection. From advanced pre-preg autoclave curing to the latest forged carbon techniques, every Scopione product is designed to outperform industry standards.

Your Journey Starts Here

At ScopioneCarbon, we don’t just sell carbon fiber parts — we deliver a performance experience backed by engineering expertise and a commitment to excellence. Whether you’re upgrading for style, aerodynamics, or lightweight performance, our team is here to ensure your satisfaction from concept to installation.

Experience the ScopioneCarbon Advantage — where craftsmanship meets innovation.

Have questions or need a custom quote? Contact our team and let’s start building your next upgrade today.